Dope dyed Ice cooling High Density Polyethylene ice cool 75D/48F 150D/48F, 200D/100F, 300D/100F, 400D/196F FDY

- Overview

- Parameter

- Inquiry

- Related Products

Specification:High Density Polyethylene ice cool 75D/48F 150D/48F, 200D/100F, 300D/100F, 400D/196F FDY

Feature: permanent ice cooling effect

Color: Raw White, Dope Dyed

Introduction:

What's Polyethylene fiber?

a)Polyethylene fiber, also called ethylene fiber, is a kind of polyolefin fiber. The material has a high thermal conductivity rate, can quickly drain the heat out, and is often used as a cooling material. After weaving the fabric with the fiber material, the fabric feels smooth and has the effect of imitation silk.

b)At the same time, the chemical bond structure of the material is stable, with certain hydrophobicity and fungicidal and anti-mildew functions, so it is a new fiber material with excellent comprehensive properties. In recent years, fibers made of high molecular weight polyethylene (HDPE) have been widely used in the fields of mattresses, cushions, mats, ice sleeves, and sportswear. Has brought everybody a brand-new life experience.

Best Choice for summer mattresses and beddings

Cool Down In Summer Season

After touching the skin, the sportswear made of the fiber will produce an instantaneous cool feeling of 1 ℃ and 2 ℃, and the temperature difference of the body surface will be reduced by 3 ℃ for a long time, which can obviously reduce the sweating rate and sultry feeling, and relieve the fatigue state.

Also The fabric made of polyethylene is single side moisture transported, you don't need to worry about the heavy sweat will wet the apparel.

How it works?

The polyethylene composite fiber is made of high molecular weight polyethylene and other fibers, improves the softness of the fiber itself and ensures the cooling effect of the fiber. In addition, the application of composite spinning technology can make the fabric satin effect and increase product richness and selectivity.

Application?

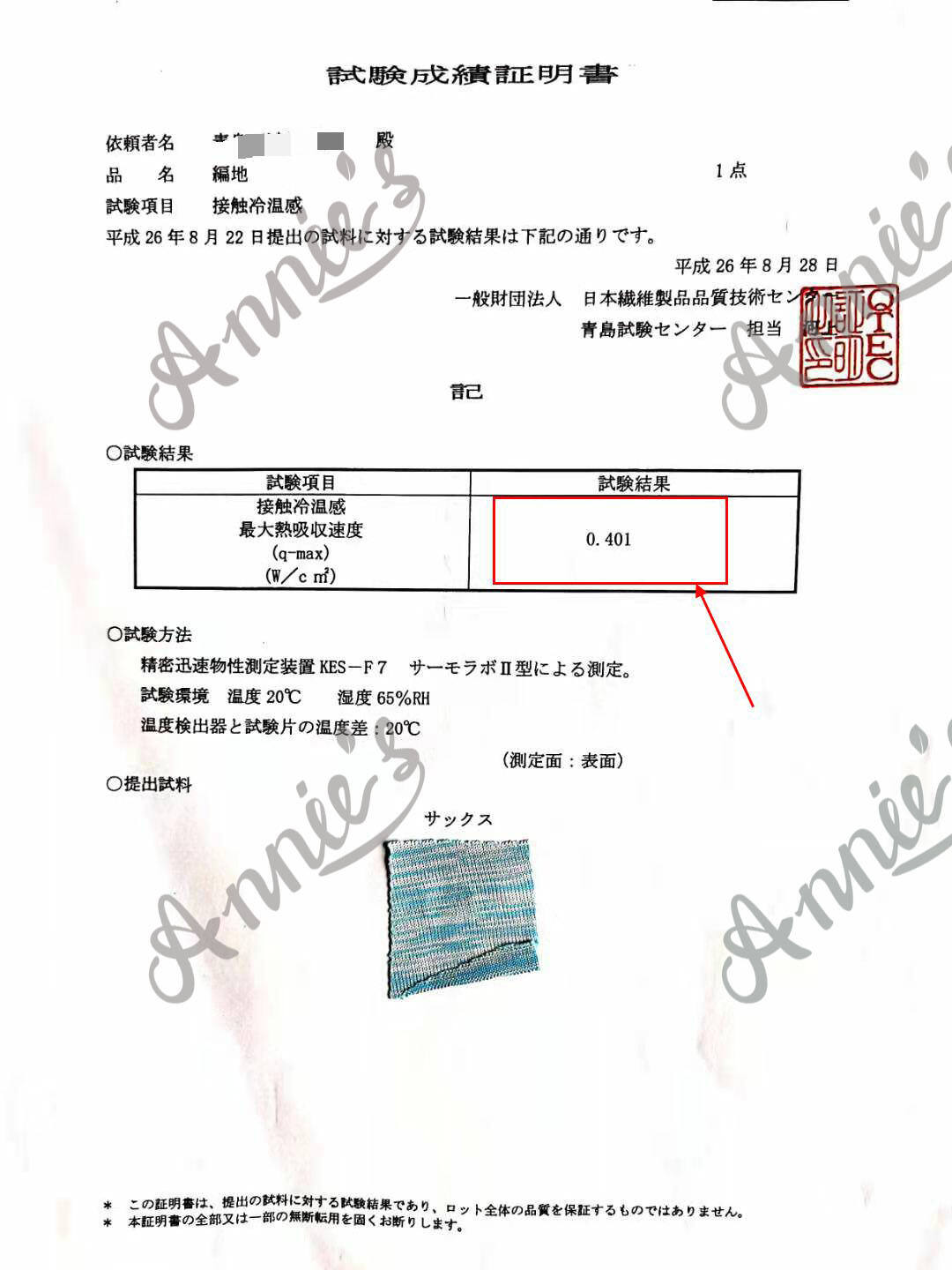

TEST REPORTS

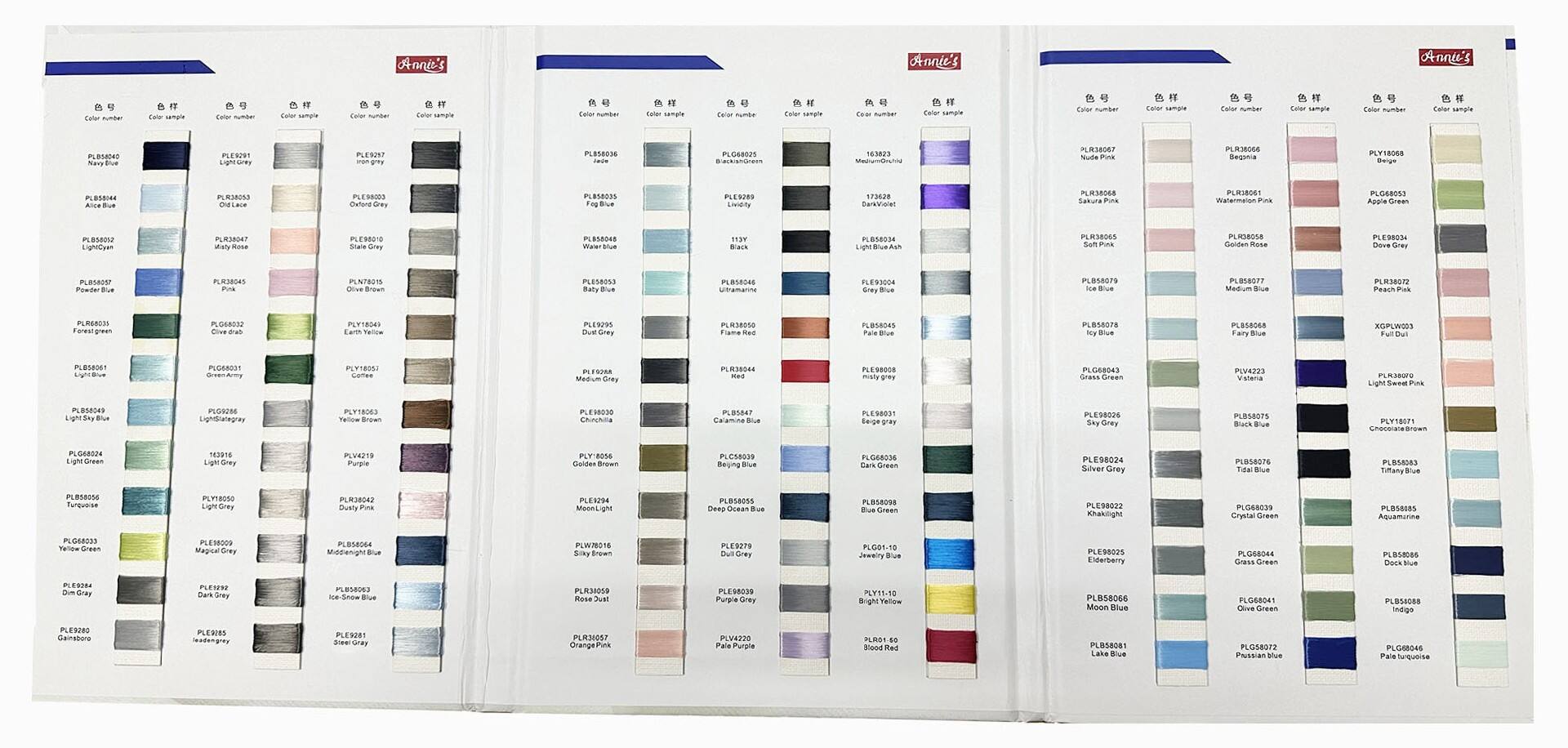

Dope Dyed

So far now we have developed dope dyed HDPE yarn so that it can satisfy customers' colorful yarn damandings.

Application:

Coconut charcoal fibers can be used for most of the apparel and hometextile products. Body can always keep dry and comfortable. After washing and drying, the sportswear can always maintain its original characteristics.

Coconut charcoal staple fibers can also be used as fillers for sportswear,underwear, ready-made clothes, bedsheets, quilts, socks, pillows and quilts. It can be used as thermal insulation fibers or as the inner layer of clothing. It can absorb the odor emitted by the human body and decompose harmful substances in the air. It has deodorizing effect.

EN

EN

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

ES

ES

TR

TR